Plastics

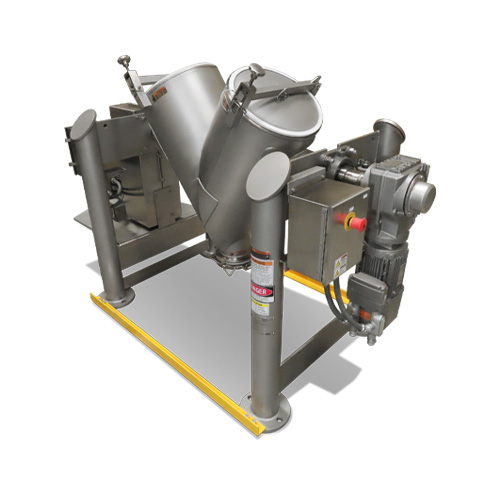

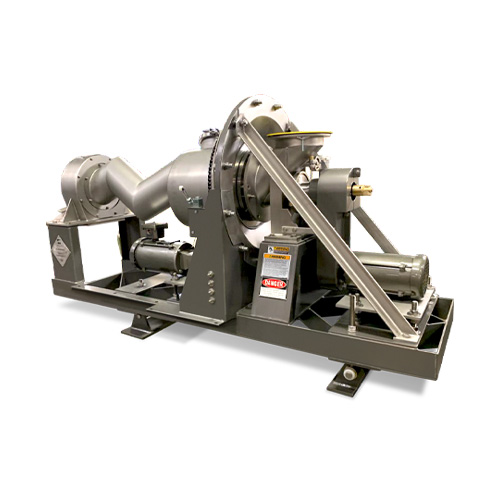

For the plastics industry, PK offers a variety of blenders and dryers to accomplish specific needs. These processes include blending wood flour with phenolic resin and preparing master batches of color concentrates for extrusion. Polymers may be impregnated with peroxide for cross-linking, while liquid plasticizers are added to resins, fillers, stabilizers, and other materials. To improve flow properties, fluorocarbon polymers are agglomerated and dried with with one of our drying products. Blending and drying can be accomplished in a single PK Solids Processor. Additional operations involve solid-state polymerization, diffusional drying, and handling dry hot melts. These methods also support increasing the intrinsic viscosity of polymers and drying rubber compounds.

Product Solutions

We Have The Solution For Your Process.

Regardless of the processing industry, PK has been providing solutions to processors for more than a century.