Blenders

Simple tumble blending is characterized by low energy input and this operation works well with formulations that are free-flowing and have similar physical properties. Patterson Kelley (PK) offers a variety of vessel geometries that allow our customers to select the best vessel for the process. The shapes include various derivations of the V blender (vee), our Twin Shell Dry Blender, as well as conical variations (such as the double cone) and common bin shapes. Portable units are available to working volumes of up to 300 liters and stationary units may be designed for batch volumes exceeding 15,000 liters.

PK Blenders

As the complexity of a formulation increases, the need often exists for imparting more energy to the process in order to yield adequate results.

Patterson Kelley satisfies this need with a selection of intensifier bars that are designed specifically to the process requirement, to create our Liquid Solids Blender®. These bars are also adapted for intimate liquid/solids mixing as well as low shear wet granulation, agitation, liquid addition and agglomeration. Spray droplet size is adjustable to accommodate a wide variety of liquid rates and liquid viscosities.

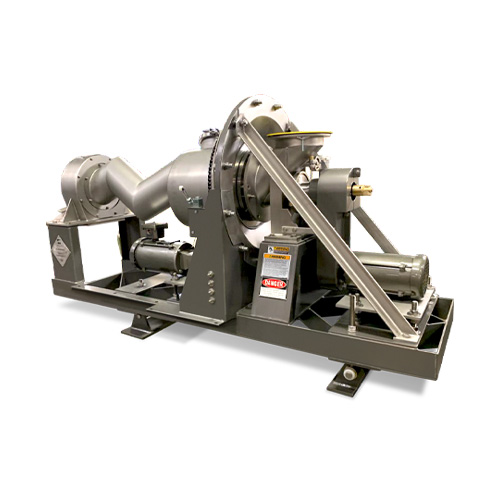

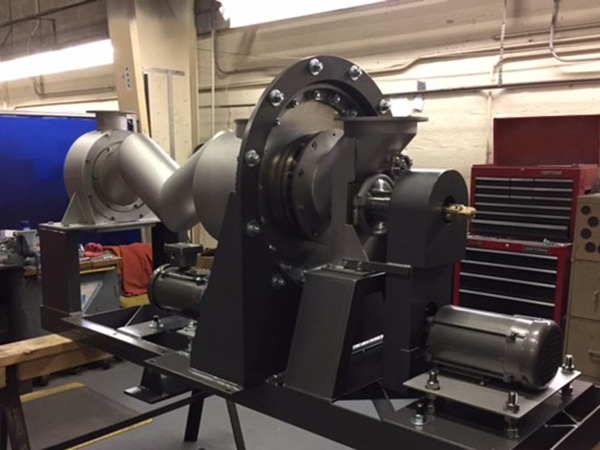

When your process throughput needs exceed what may be economically accomplished in batch units, PK meets that need with a full line of continuous processing equipment.

The continuous systems are designed to match the processing characteristics of our batch operations and they are available in all the unit operations seen in our batch blending equipment. The product line is broadly divided into two areas – large scale and small scale. The large scale line is capable of several thousand metric tons per hours. The small scale addresses low throughput pharmaceutical applications that are Process Analytical Technology compliant and have near real time analysis of process attributes.

Complete Process Systems from One Single Source

As a subsidiary of Carrier Process Equipment Group (CPEG), additional thermal processing and dry solids processing equipment is available to supplement and build out your production line. From PK’s blending and mixing equipment to a wide range of other processing technologies and automation options, our team of experts can help determine the most suitable products for your manufacturing line.