Lab Testing & Rentals

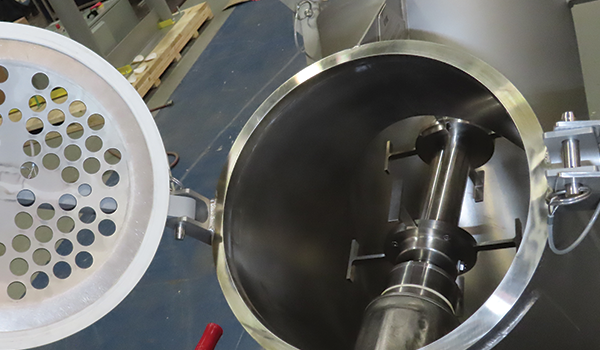

Our state-of-the-art lab testing facilities in Tonawanda, NY allows you to evaluate Patterson-Kelley blenders with your own materials before committing to a purchase. We provide detailed performance data, blending trials, and expert recommendations to ensure you get the perfect solution for your process.

PK blenders

Dryer & Flakers

aVAILABLE LAB UTILITIES

Evaporation & distillation equipment

wet lab

Annex fabrication shop

CPEG Innovation Lab

Our customers have full access to the CPEG Innovation Center and testing laboratory in Louisville, KY to solve unique processing issues and verify that custom-engineered equipment meets final product requirements. The Innovation Center provides powder and bulk solids testing utilizing the industry’s most comprehensive line of equipment. The state-of-the-art facility provides an innovative pilot-scale testing experience that simulates real-world process line environments.

Rental Equipment

When testing in one of PK’s laboratories is not feasible, equipment can be rented and shipped to your facility. This provides real-world testing and validation of equipment performance under your specific operating conditions, ensuring it meets throughput, efficiency, and product quality requirements. Each component of the rental system is assembled on a portable frame for easy installation and hookup to utilities. Our rental equipment availability can vary but may include: