Dryers

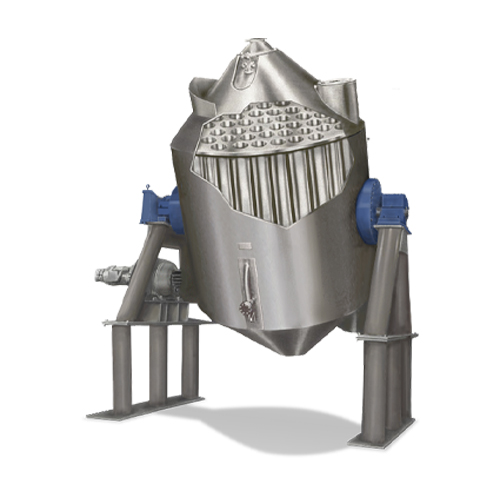

PK uses a jacketed vessel and tumbling motion to maximize heat transfer and achieve uniform drying—even under vacuum. This unique design enables simultaneous blending, drying, and chemical reactions in a single, streamlined step. Ideal for polymerization, solvent removal, metal powder treatment, and more. PK Dryers are engineered for lasting performance and optimal efficiency. Built with heavy-duty construction and smart design features, they ensure consistent mixing, faster processing, and easy maintenance—minimizing downtime and keeping your production running smoothly.

PK Dryers

Patterson Kelley’s (PK) Tubular Vacuum Dryers (TVD) can process (dry and/or polymerize in the solid state) free-flowing solid material more rapidly than conventional vacuum dryers.

This is made possible by a greatly enhanced heat transfer surface area typically 3 to 7 times larger than similar sized traditional systems. Factors such as increased operating temperature and vacuum capacity also play an important role. The wide range of sizes available allow both high-volume processors and smaller-scale custom processors to enjoy the benefits obtained from using these dryers/solid states. Nylon and PET are among the polymers that have been successfully processed.

Patterson Kelley (PK) Solids Processors are configured with heating and vacuum packages that offer the ability to process complex formulations through a processing scheme.

The process may begin with a dry mixing step, followed by wet granulation, vacuum drying and lubrication. Containment and control are satisfied by maintaining the process within a single vessel until all unit operations have been completed. PK Vacuum Tumble Dryers operate exclusively for the drying step and are available in a variety of shapes. They may be designed for high and low temperature applications as well as for many different solvent systems.

Complete Process Systems from One Single Source

As a subsidiary of Carrier Process Equipment Group (CPEG), additional thermal processing and dry solids processing equipment is available to supplement and build out your production line. From PK’s drying equipment to a wide range of other processing technologies and automation options, our team of experts can help determine the most suitable products for your manufacturing line.