FAQs

We assign a dedicated team to address your questions and needs thorughout the life of a project. Since the PK line of blenders and dryers offer many options and customizable features, below includes some frequently asked questions and answers to ensure that you are confident in your choice to partner with PK Blenders.

PK Blenders assigns a dedicated product engineer to each customer’s project, ensuring a single point of contact who understands your process, timeline, and goals. This personalized approach streamlines communication, accelerates decision-making, and provides consistent support from initial design through final delivery.

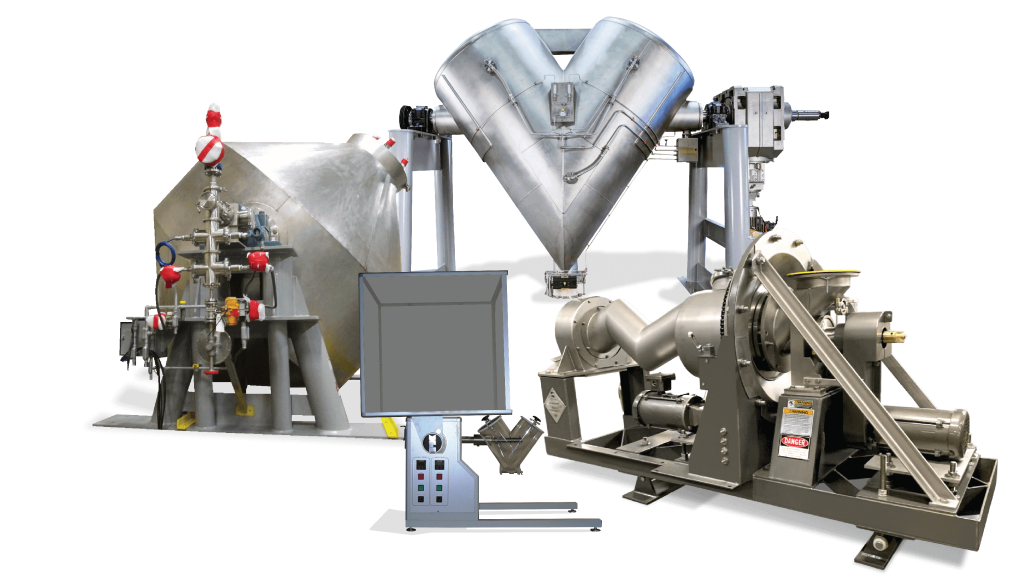

PK Blenders designs and manufactures a full line of tumble blenders, dryers, and multipurpose processors, including Double Cone Blenders, Twin Shell Blenders, Slant Cone designs, Cross Flow Blenders, and Tubular Vacuum Dryers. Each system is engineered for efficient, uniform processing while protecting product integrity.

Tumble blenders gently rotate a vessel, creating a tumbling action that blends materials without the high shear forces of intensified mixers. This makes them ideal for fragile, friable, or temperature-sensitive products. The rotating motion ensures uniform distribution of solids, consistent drying, and precise heat and mass transfer.

Gentle mixing action reduces product degradation.

Uniform exposure to heat and airflow for even drying.

Non-intensified design means fewer moving parts and lower maintenance.

Available in standard and slant-cone options to improve mixing efficiency and discharge.

ASME Code rated vessels ensure safety and compliance in critical applications.

The PK Cross Flow features an uneven shell design that creates unique axial flow, ensuring faster, more efficient mixing compared to Double Cone or Twin Shell blenders. It offers quick charging/discharging, easy cleaning, and energy-efficient operation—making it one of the most precise tumble blenders available.

The PK Solids-Processor is a multi-functional system that handles blending, coating, agglomerating, granulating, vacuum drying, heating, and cooling—all in a single machine. This eliminates the need to transfer product between multiple pieces of equipment, saving space, time, labor, and utilities while reducing contamination risk.

Our equipment is used across industries including pharmaceuticals, nutraceuticals, food, chemicals, cosmetics, soap, polymers, and metals. Common applications include:

Pharma: API injection, solvent removal, pre-mixes

Food & Nutraceuticals: vitamin blends, coatings, fragile powders

Polymers: Nylon, PET, polymerization, low-moisture drying

Metals: powders, oxides, alloys, and specialty blends

PK Blenders and dryers are available in a wide range of capacities:

Blenders: From 16 quarts up to 300 cubic feet.

Tubular Dryers: 1,000–20,000 lbs/hr throughput, with 16- or 26-tube designs at 12 or 16 ft lengths.

Tumble Dryers: Flexible sizes (4, 8 & 16 quarts, 1–375 cubic feet) to suit batch or production-scale needs.

All product contact surfaces are available in 316L stainless steel, ensuring compliance with strict food safety and pharmaceutical standards. Stainless steel provides superior corrosion resistance, durability, and easy cleaning—critical for industries where contamination control is essential.

ASME Code rated vessels for pressure and vacuum safety.

Ultra-tight vacuum seals (to 0.5 mmHg) to prevent contamination.

Optional nitrogen purge systems to prevent oxidation.

Automation and process monitoring for precise control and batch recording.

Yes. Systems are custom-engineered to meet application-specific needs, with options for:

Post lift systems to handle bin sizes up to 50 cubic feet.

Auxiliary heating, cooling, and vacuum skids for process optimization.

Multiple orientations, shapes, and configurations for flexible material flow.

Density ratings from 62 lb/ft³ up to 500 lb/ft³ depending on design.

Selecting the right equipment depends on factors like batch size, material characteristics (density, particle size, friability), moisture content, and throughput requirements. For example, a Double Cone Blender works well for free-flowing powders, while a Cross Flow Blender improves mixing speed for uneven particle sizes. A Tubular Dryer is ideal for continuous, high-volume processing, while a Vacuum Tumble Dryer offers gentle, low-temperature drying for fragile or heat-sensitive materials.

Routine maintenance is minimal due to the non-intensified design and few moving parts. Standard care includes inspecting seals, lubricating bearings, and ensuring vessel surfaces remain clean and free of residue. For dryers, monitoring vacuum integrity and heating systems is essential. With proper preventive maintenance, PK Blenders and Dryers can deliver decades of reliable service.

View All Equipment

To see more specific specs and details on each type of equipment, click the button below.

Free Download

Download our Capabilities Brochure for more information.