Last updated on February 10th, 2026 at 12:16 pm

Understanding V-Blender Speed for Pharmaceutical Excellence

Determining the speed for pharmaceutical blending with a V blender is critical to product quality, compliance, and efficiency. Here are the key figures:

Quick Answer: Typical V-Blender Speeds

- Standard Operating Range: 5-25 RPM (revolutions per minute)

- Optimal Performance: 50-80% of critical speed

- Lab-Scale Blenders (60-300L): Typically 12-15 RPM

- Production-Scale Blenders (500-1500L): Typically 10-12 RPM

- Intensifier Bar (when equipped): 1200-3000 RPM for lump breaking

- Typical Blending Time: 5-15 minutes per batch

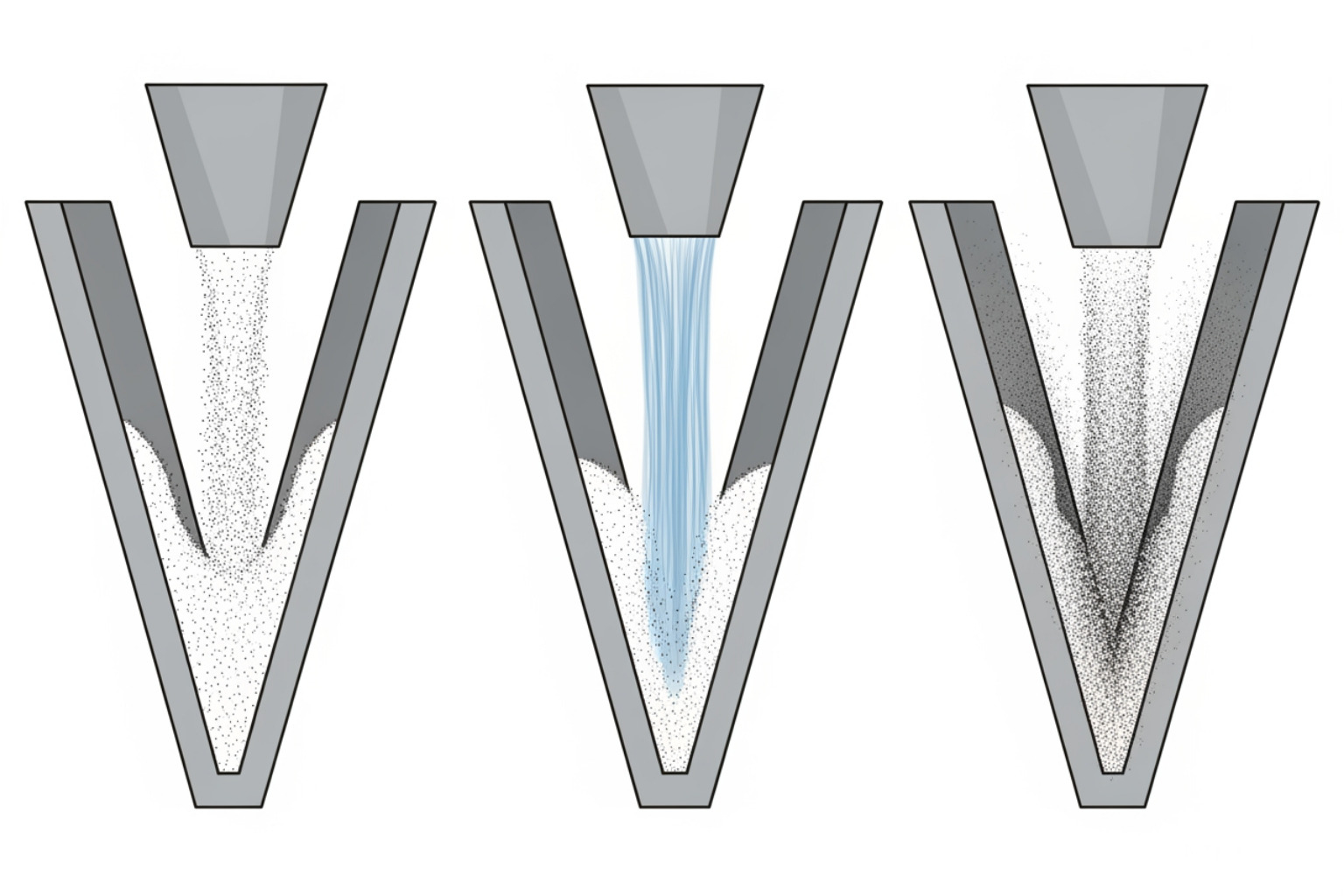

In pharmaceutical manufacturing, the correct rotational speed ensures blend uniformity required by GMP standards while protecting delicate materials. The V-blender uses a gentle diffusion-mixing mechanism in which materials cascade, split, and recombine, achieving homogeneity without aggressive shear. This makes it ideal for fragile granules and cohesive powders.

However, the optimal speed depends on material properties, fill levels, and batch size. Operating too slowly reduces efficiency, while running too fast risks segregation, dusting, or centrifuging, conditions in which materials adhere to the vessel walls. This guide explains the science behind V-blender speeds and how to optimize your process to achieve validated results.

The Science of Speed: Understanding Critical Velocity and RPM

In a V-blender, rotational speed is about balancing centrifugal and gravitational forces. At the right speed, materials cascade, split, and recombine. Too slow, and they don’t mix; too fast, and they stick to the walls. Tumbling blenders rely on gravity for this diffusion mixing. The Froude Number, which compares inertial to gravitational forces, helps define the optimal RPM for blend uniformity.

Understanding these principles is fundamental to answering what is the speed for pharmaceutical blending using v blender. For more insights into optimizing your powder processing operations, explore our Blending Powder Processing solutions.

What is ‘Critical Speed’ in a V-Blender?

Critical speed is the rotational speed where centrifugal force overpowers gravity. At this point, powders are pinned against the vessel walls rather than cascading, a phenomenon known as centrifuging. This must be avoided.

When centrifuging occurs, mixing efficiency drops to zero, particles stick to the inner surfaces, and blend uniformity is compromised, putting product quality at risk. The critical speed depends on the blender’s diameter; larger blenders have lower critical speeds. The Froude Number helps calculate this, with a value approaching 1 indicating the onset of centrifuging. Operating well below critical speed is essential for proper mixing.

The Optimal Speed Range: Finding the Sweet Spot

The best performance of V-blenders is typically achieved at rotational speeds of 5 to 25 RPM. More precisely, the optimal speed is 50% to 80% of the calculated critical speed. This range creates the ideal cascading motion for diffusion mixing without excessive shear or particle damage.

Blender size is a key factor. Smaller lab-scale V-blenders (60-300 liters) typically operate at around 15 RPM, while larger production units (500-1500 liters) operate at 12 RPM or lower. The general rule is: the bigger the blender, the slower the optimal speed.

For free-flowing materials, mixing often depends more on the total number of revolutions than the rotation rate. A batch might need 150-200 total revolutions to achieve uniformity, a valuable principle for scale-up. Understanding particle behavior continues to evolve through scientific research on particle flow in V-blenders, improving process optimization.

What is the Speed for Pharmaceutical Blending Using a V-Blender?

The practical answer to what is the speed for pharmaceutical blending using v blender is: it depends on your material and batch size. Modern pharmaceutical-grade V-blenders, like those from PK Blenders, feature a Variable Frequency Drive (VFD) for precise control over rotational speed. A VFD allows you to fine-tune parameters for each formulation and provides a gentle “soft start” to protect the motor and prevent jarring delicate powders.

Material characteristics, batch size, and desired uniformity all determine the optimal speed. A small batch of a free-flowing blend might run at 15 RPM, while a large batch with a cohesive API may need 10 RPM to prevent dusting. At PK Blenders, we help manufacturers dial in these parameters. Learn more about how we support Pharmaceutical applications with equipment designed for your industry’s standards.

How Material Properties Influence Blending Speed

Your powder’s characteristics are as important as the blender’s capabilities. Consider these factors:

- Particle Size and Density: For materials with significant density differences, a slower speed prevents segregation, where heavier particles settle.

- Cohesiveness: Cohesive powders tend to clump. While V-blenders are low-shear, operating at the higher end of the optimal speed range can help break up weak agglomerates. Watch for dusting.

- Friability: Fragile granules can be damaged by high speeds, altering their properties. The V-blender’s gentle action, especially at slower speeds, is ideal for these materials.

- Granules vs. Fine Powders: Fine powders require lower speeds to prevent dusting and static buildup. Fragile granules also need slower speeds to maintain integrity. Free-flowing granules are more forgiving and can often handle higher speeds.

How Fill Level Affects Blending Speed and Time

The fill level dramatically impacts blending. We recommend filling your V-blender to 50% to 60% of its total capacity. This provides the necessary headspace for materials to split, cascade, and recombine efficiently.

Underfilling (below 40%) results in insufficient particle-to-particle contact, leading to poor mixing. Overfilling (above 70%) eliminates the void space needed for particle mobility. The material rotates as a single mass, and the diffusion mechanism fails. This can double or triple blend times and may prevent homogeneity altogether. Overfilling also strains the motor, complicates discharge, and makes cleaning more difficult.

Maintaining a 50-60% fill level ensures your materials can move and mix efficiently, regardless of the rotational speed.

Operating Your V-Blender for Peak Performance

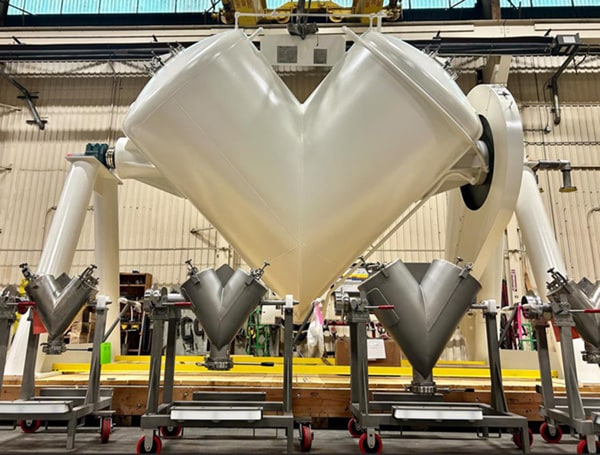

Achieving peak performance involves careful process validation (IQ/OQ/PQ), understanding blending time, and knowing how to use features like the intensifier bar, all within a cGMP compliance framework. At PK Blenders, our Twin Shell V Blender is designed to meet these rigorous demands, delivering consistent, reliable performance.

A well-operated V-blender, with the correct speed and fill level, creates a gentle tumbling action that achieves uniformity and deagglomeration without damaging ingredients.

Determining the Optimal Rotational Speed for a V-Blender in Pharmaceutical Blending

Finding the perfect rotational speed is a process of science and experimentation. Start with the baseline 5-25 RPM range. For smaller lab units, 15 RPM is a good starting point, while larger production blenders often start around 12 RPM. These speeds keep you within 50-80% of critical speed, ensuring proper cascading motion.

Most pharmaceutical blends achieve homogeneity in 5 to 15 minutes. For free-flowing powders, the total number of revolutions is often more critical than the speed itself. However, material properties are paramount. Fragile granules require slower speeds, while robust materials can handle higher speeds. This is why we offer Lab Testing services to determine optimal parameters for your specific formulations.

Process Analytical Technology (PAT) tools, like NIR sensors, can monitor blend uniformity in real-time, allowing you to stop the process at the precise moment of homogeneity. This data, combined with programmable recipe systems, ensures batch-to-batch consistency.

Here is a practical reference for typical V-blender speeds:

| Blender Size (Liters) | Max. Mixing Volume (Liters) | Recommended Mixing Rotation (RPM) |

|---|---|---|

| 60 | 35 | 15 |

| 150 | 80 | 15 |

| 300 | 160 | 15 |

| 500 | 260 | 12 |

| 1000 | 500 | 12 |

| 1500 | 750 | 12 |

Keep in mind: these are starting points. Your optimal speed depends on material properties and fill level and must be validated for each application.

Does an Intensifier Bar Change the Recommended Speed?

Yes, an intensifier bar dramatically changes the process. It’s an optional high-speed agitator that introduces high-shear mixing into the gentle blending environment. While the vessel tumbles at 5-25 RPM, the intensifier bar spins at 1200-3000 RPM.

This is powerful for lump breaking, deagglomeration, and incorporating small amounts of liquid during wet granulation. The V-shell provides gentle turnover while the bar delivers localized high-shear action.

However, this high shear can cause particle attrition with fragile materials. The bar’s speed and run time must be carefully optimized. Intensifier bars also add internal components that require meticulous cleaning protocols to meet cGMP standards and prevent cross-contamination. Advanced tools such as Discrete Element Method (DEM) simulations can help optimize the use of intensifier bars by modeling particle flow, as detailed in studies on manufacturing process simulation. When using an intensifier bar, you optimize two speeds that work in harmony.

Achieving Uniformity: Consequences and Optimization

In pharmaceutical manufacturing, exceptional blend uniformity—typically a relative standard deviation (RSD) of less than 2% for APIs—is non-negotiable. It ensures every dose contains the correct amount of medication. Achieving this precision requires careful speed control and process validation. Failure can lead to segregation, particle attrition, and inconsistent products. At PK Blenders, our Lab Testing services help you identify optimal blending parameters before full-scale production.

Consequences of Incorrect V-Blender Speed in Pharmaceutical Blending

Operating outside the optimal speed range has significant consequences for product quality. Answering what is the speed for pharmaceutical blending using v blender correctly is critical.

- Running too slowly results in inefficient mixing, longer blend times, and poor homogeneity. APIs may not be distributed evenly, a critical quality failure.

- Running too fast causes segregation, where particles separate by size and density. It can also cause particle attrition, damaging fragile granules and altering their physical properties. Other issues include dusting, static charge buildup, and lubricant over-mixing, which can result in poor tablet hardness and delayed disintegration.

How to Adjust Speed for Consistent Blend Uniformity

Achieving consistent uniformity requires a systematic approach to optimization.

- Use a Variable Frequency Drive (VFD): This is your primary tool for precise RPM adjustment and soft starts, protecting both the motor and your materials.

- Program Blending Recipes: Use your control system to save protocols for RPM, duration, and intensifier bar settings. This ensures reproducibility and eliminates operator variability.

- Optimize and Validate: Start with material testing to understand particle characteristics. Run small-scale trials to observe behavior and take samples to analyze uniformity. Use this data to adjust speed and time. This iterative process (test, measure, adjust) helps you find the optimal parameters.

- Lock in with Validation: Once optimized, use IQ/OQ/PQ to validate that your process is robust and reproducible, meeting regulatory standards.

- Integrate PAT: For critical formulations, Process Analytical Technology (PAT) tools like NIR sensors provide real-time feedback, allowing you to stop the process at the exact moment of homogeneity.

When you need equipment to support this level of precision, Request a Quote for your blending needs and let us help you optimize your process.

Conclusion: Mastering Your Pharmaceutical Blending Process

Correctly determining what is the speed for pharmaceutical blending using v blender is foundational to your manufacturing process. The right rotational speed ensures consistent blend uniformity, protects particle integrity, and leads to effective medications.

We’ve covered the science of critical speed, the optimal 5-25 RPM range, and the importance of material properties and fill levels. Modern tools such as VFDs, PAT, and optional intensifier bars provide the control required for precise, repeatable results. Mastering V-blender speed improves efficiency, reduces rejected batches, and ensures final product quality.

At Patterson-Kelley, we partner with you to optimize your entire blending process, guided by the principles of Quality by Design (QbD). Our expertise and lab testing facilities help you develop robust, validated processes from development to full-scale production.

If you’re ready to lift your pharmaceutical blending, our advanced Twin-Shell V-Blenders offer the precise speed control, GMP-compliant design, and reliability you need. Let’s work together to master your process.