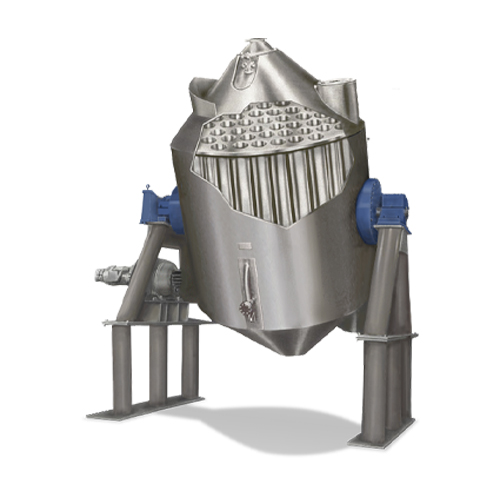

Tubular Vacuum Dryer

The 300 cu. ft. Tubular Vacuum Dryer (TVD) has six times more heat transfer surface than any other conical vacuum dryer of the same size making it a smart replacement option. Process applications include solid state polymerization of polymers and drying polymers to low moisture content.

Common applications include polymerization, Nylon, PET and more.

Vacuum Drying

The Tubular Vacuum Dryer (TVD) is engineered for high-efficiency polymer drying and solid-state polymerization. It’s expanded heat transfer surface accelerates drying cycles and ensures consistent moisture removal throughout the material. The system maintains an ultra-tight vacuum of 0.5 mm Hg or lower to protect product quality, and optional nitrogen purging safeguards against oxidation. With jacket temperatures reaching up to 500°F and advanced automation for precise batch control and process monitoring, the TVD delivers reliable, uniform results while minimizing contamination and processing time.

Features & Benefits

+ Options

Free Download

Download our dryers brochure for more information.