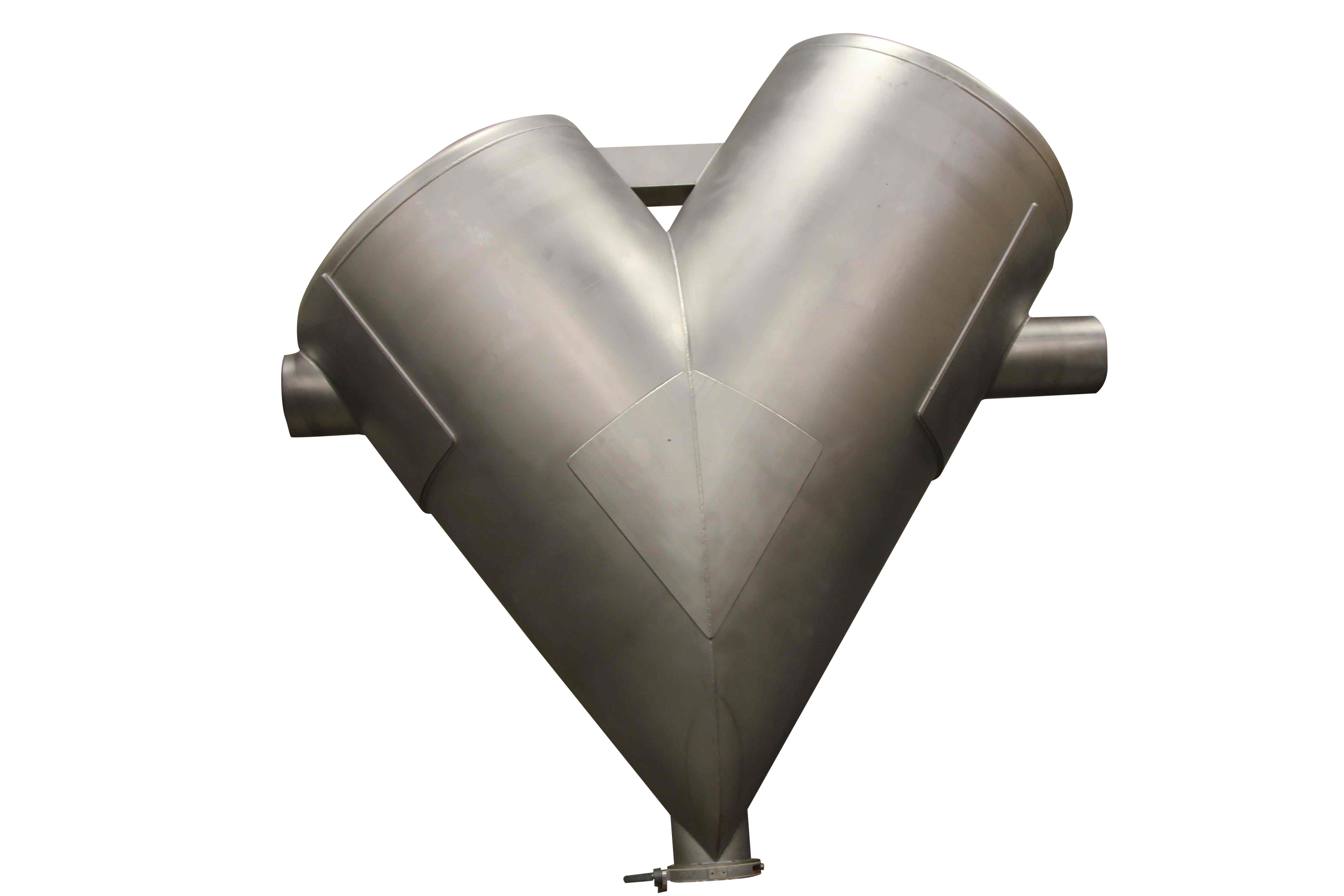

Twin Shell Dry Blender®

The PK Twin Shell Dry Blender overcomes discharge problems and creates additional mixing action at the center with two opposed simple cylinders formed in a “V” making for faster, more efficient blending. This blender can handle extremely delicate to heavy abrasive materials.

Common applications include pharmaceutical formulation, metal blending, rat poison, food ingredient pre-mixes, silica and ceramic blending, wet blending and more.

Tumble Blending

The PK Twin Shell Dry Blender is a versatile industrial blender designed for efficient dry powder mixing across a wide range of applications. As one of the most popular choices for pharmaceutical blending, food ingredient mixing, metal powders, ceramics, and chemical formulations, it delivers consistent, uniform results while protecting delicate materials. Its V-shaped twin shell design ensures thorough blending and faster cycle times, while customization options such as intensifiers, discharge valves, and automated PLC controls make it adaptable to virtually any production process. Built with 316L stainless steel contact surfaces and available in multiple orientations and capacities, this dry blender provides a reliable solution for manufacturers seeking efficient, dust-tight, and hygienic powder mixing.

Features & Benefits

+ Options

P-K Cross-Flow® Option

The uneven design of the shell creates a unique axial flow for quick, efficient product exchange, and is the most precise blender available.

Twin Shell Dry Blender®

Faster, More Efficient Blending With Our

V-Design

Free Download

Download our blenders brochure for more information.