M.V.P. Blending System®

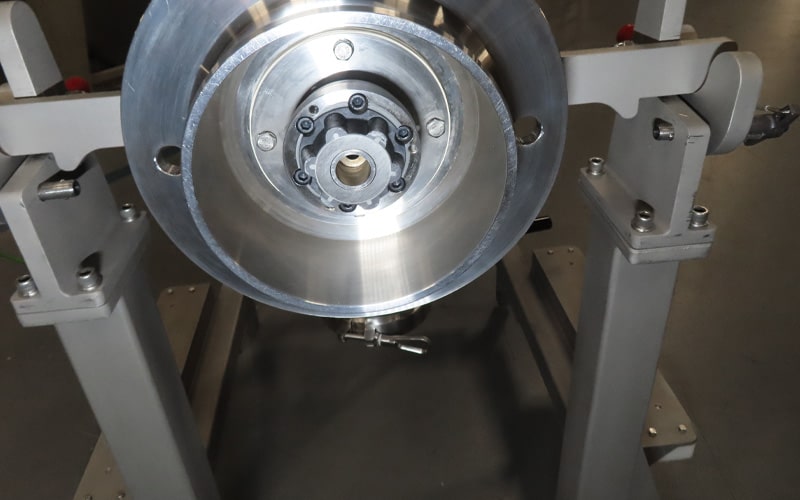

Our Multi-Vessel Processor can be configured as a portable, stand alone blending system which is ideal for small suites and research applications while larger suites may utilize our fixed M.V.P. designs configured with post lifts. The adaptable unit accepts multiple sizes and geometries, making for zero down time between batches.

Common applications include pill color coatings, Teflon & Gore-Tex, Latex, Oxi Clean, fully automated lines.

Tumble Blending

The PK Multi-Vessel Processor (M.V.P.) is engineered for maximum flexibility in powder blending, making it a top choice for pharmaceutical, chemical, and specialty material processing. By accommodating multiple vessel types—including twin shell, cross flow, double cone, and slant cone—the system handles a wide range of batch sizes, with a max bin volume of 50 cubic feet. Its design minimizes downtime, streamlines cleaning, and supports both R&D environments and full-scale production, delivering reliable, repeatable results across diverse applications.

Interchangeable Attachments

By accommodating multiple vessel types—including Twin Shell, Cross Flow, Double Cone, and Slant Cone—the system allows manufacturers to handle a wide range of batch sizes and product types without the need for multiple blending rooms.

Features & Benefits

+ Options

M.V.P. Blending System®

Multi-Vessel Processor for Pharmaceutical, Chemical & Specialty Material Processing

Free Download

Download our blenders brochure for more information.